DK 350

The NortheK Dall Kirkham 350 f 20 is a high resolution instrument performing extremely well, particularly for the observation of small bright objects: it is a dream come true for many amateur astronomers. This instrument is the answer to all those who have a good experience and are enthusiasts about planet imaging.

The project of this optical tube incorporates all the best technological solutions available for a Dall Kirkham scheme, such as the StabilobloK 35 cell, the composite tube UnitorK 35 and the modified 2.5″ Feather Touch focuser. Please note how the focuser is included in the price of the FT motor Mkit 30. This highlights a very important aspect: without an electronic system it is nearly impossible to make the most of the outstanding performance of this telescope (as for the Mkit 30 performance, please refer to the “Focusing” page in this web site under “Technical topics” or directly to the Feather Touch web site).

This is a very standard telescope, intended for users with a good experience in this kind of target and able to get the most also out of the equipment (i.e. seeing, setting up) to thoroughly exploit their investment.

The NortheK DK 350 is a highly specialized tube ideal for the semi-professional single user in the high resolution but also right for a group of amateurs with mixed abilities and experiences.

Better than words the pictures in our web site explain the characteristics of this instrument. Please pay attention to the particular details of this tube, all the technical solutions adopted to face any technical problem and note in particular the aperture f 3 of the primary mirror which allows the reduction of the lever size.

Considering the high standard of this instrument, we are available to discuss any request of modification to the original project.

Description

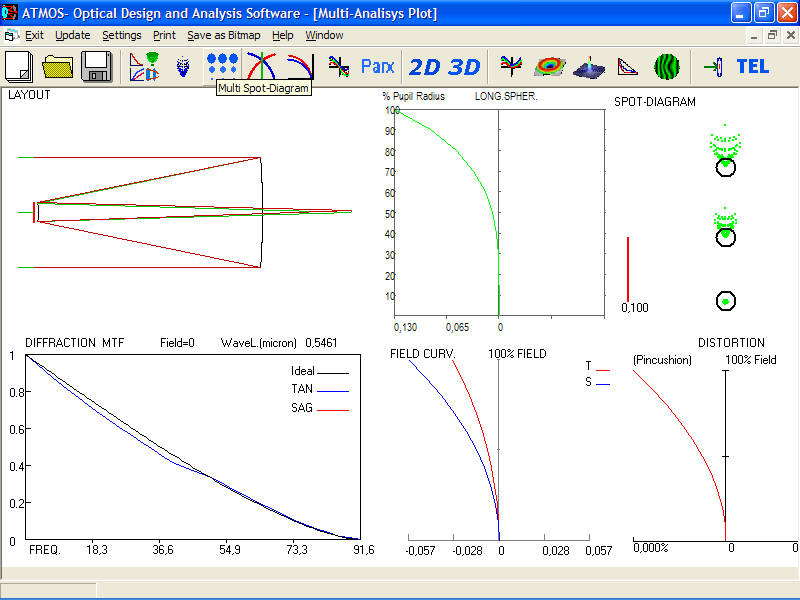

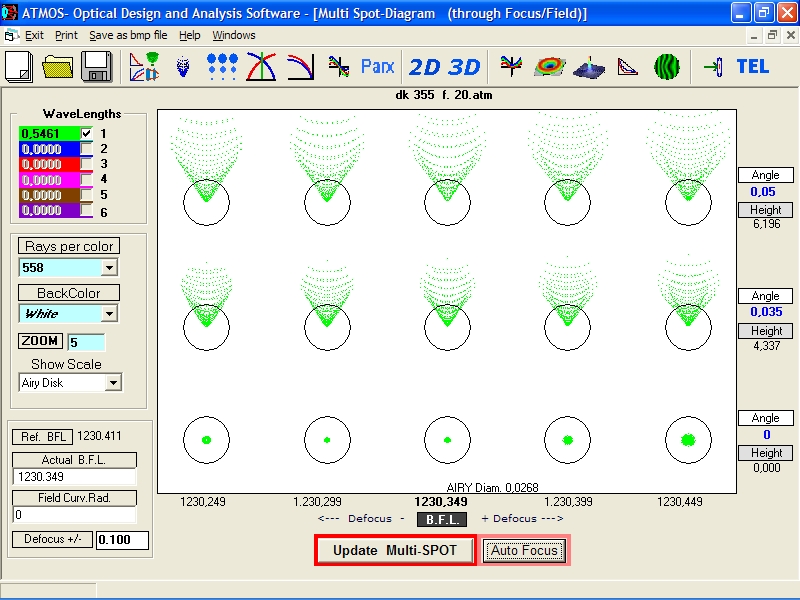

The NortheK DK 350 is a Dall Kirkham optical tube (parabolic primary mirror and spherical secondary mirror) designed for astronomical observation in high resolution.

It is the best available on the market of mass produced optical tubes and, as such, it incorporates as many innovative and highly technological solutions as possible. Its performance guarantees the optimum value for money.

As far as the optics were concerned, we opted for Supremax 33 from Schott and chose to keep the thin disc (35 mm) in order to allow the vitreous mass to follow the temperature variation during the observation session in the best way. Not only: we added an extra threee radial fans in addition to the three at the rear (60 mm diameter) to ease the dispersal of the warm air layer on the coated surface. This is a huge advantage in high resolution because is significantly improves the optics performances. the radial and axial fans (optional) can be operated by an electronic control unit to adjust the speed and, because they are mounted on anti-vibration supports, they can turn at low speed even during the observation session.

The platform support for the primary mirror is similar to the one used in the 250 series but with increased dimensions and capacity. The mechanics have been built with laminates in Halo 25 alloy, all flattened and with surface accuracy of 0,1 mm/sqmt and a thickness accuracy of 0,05 mm, in order to achieve the aim of not interfering whit the optical discs at all.

To guarantee the best support without edge deformation, 6 very strong side pads are provided, incorporating a system for the control of the parallelism of the optical glass discs (normally varying between 0,5 and 0,7 mm). Further details can be found in the technical data sheet of the StabilobloK 35 primary’s cell.

The focusing provided for this model is 2,5″ and, althoug quite long for this diameter, mechanically it performs very well. It’s no good to have an outstanding optical tube if its focusing is affected by every movement. Because this is an optic with a 7 mt native focal length, it is easy to understand how important it is to maintain the optical and mechanical axis. The key to this problem is the self-centring focusing system.

The UnitorK 35 tube structure represents the ultimate evolution of the lighter and smaller UnitorK 25. This improved version has been engineered to allow a better control of the forces involved with bigger masses and the carbon structure is also stronger as the aim is to totally avoid any flexions or twisting of the truss tube. The first section of the truss is protected by a very thin aluminium sheet (0,8 mm): a light and elegant but cost-effective solution. This was preferred to a carbon sheet because, from a mechanical point of view, it wouldn’t have given any significant advantage.

The support for the secondary mirror is the well-tested AxyS A1, perfectly fit for this low obstruction instrument, while the spiders have been increased to 4 in order to improve the AxyS stability on longer levers.

If you want to read in detail the characteristics of UnitorK 35, AxyS A1, StabilobloK 35 please go to “Precision Engineering” section of this website and you will be able to appreciate the highly technological content of this telescope.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||